Briquettes are a type of biofuel that are made from compressed organic matter or biomass. They serve as a renewable energy source and can be utilized in various applications, ranging from industrial heating to household cooking. The briquette making process is an essential aspect of biomass conversion technology and has gained attention as a sustainable solution to energy needs.

This article will delve into the briquette making process, detailing the steps involved and the benefits of using briquettes as an alternative energy source.

Understanding Biomass

Before explaining the briquette making process, it is crucial to understand what biomass is. Biomass refers to organic materials such as wood, agricultural residues, and other plant-based materials. These materials contain carbon and can be used to produce energy when burned, making them an environmentally friendly alternative to fossil fuels.

The demand for renewable energy has led to an increased interest in converting biomass into briquettes, which are easier to handle, transport, and store compared to loose biomass.

Step 1: Collection of Raw Materials

The first step in the briquette making process involves the collection of suitable raw materials. Common biomass sources include agricultural waste (like rice husks, straw, and sugarcane bagasse), sawdust, and wood chips. It is essential to select high-quality materials that have a low moisture content, as this enhances the briquette’s combustion efficiency. The collected biomass should be free from contaminants, such as plastics or metals, which can release harmful emissions when burned.

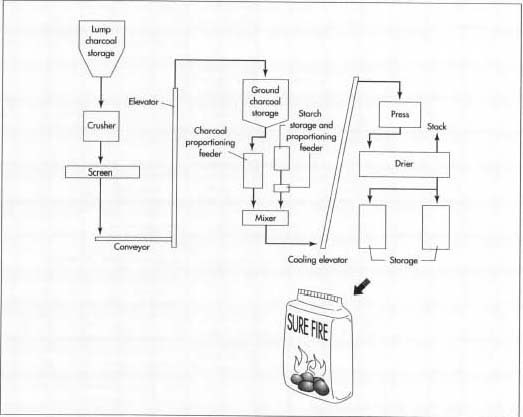

Step 2: Size Reduction

Once the raw materials are collected, they must be processed to achieve a uniform size. This is done through a size reduction process that typically involves shredding or grinding the biomass into smaller particles. The optimal particle size for briquette production is generally around 2-5 mm. Reducing the size of the materials enhances the surface area, allowing for better compaction and improving the quality of the final briquette.

Step 3: Drying

Drying is a critical step in the briquette making process. Biomass that contains high moisture levels (above 15%) can result in poor briquette quality and lower heating values. Therefore, the ground biomass needs to be dried to reduce its moisture content. This can be achieved through natural methods, such as sun drying, or using industrial drying equipment. The target moisture level for briquette production is typically around 10% or lower.

Step 4: Mixing

Once the biomass is dried, it may need to be mixed with a binder to improve the binding properties of the briquettes. Common binders include starch, molasses, or even a portion of the shredded biomass itself. The binder helps in holding the particles together during the compression phase, resulting in denser and stronger briquettes. The mixing process ensures that the binder is evenly distributed throughout the biomass.

Step 5: Compression

The compression of biomass is the critical step in the briquette making process. This is typically done using a briquetting machine, where the prepared biomass mixture is subjected to high pressure. The compression causes the lignin in the biomass to soften and act as a natural binder, helping to hold the briquette together. The pressure and temperature applied during compression significantly affect the density and quality of the briquettes produced.

Step 6: Cooling and Packaging

After compression, the briquettes are usually hot and need to be cooled before they can be handled or packaged. Cooling can be done naturally or in a controlled environment. Once cooled, the briquettes can be packaged for distribution. Packaging is essential for protecting the briquettes from moisture and contaminants, ensuring that they maintain their quality during storage and transport.

Benefits of Briquettes

The briquette making process results in several benefits, making briquettes a favorable option for energy production:

- Renewable Energy Source: Briquettes are made from sustainable materials, reducing reliance on fossil fuels and contributing to lower greenhouse gas emissions.

- Waste Management: Utilizing agricultural and industrial waste for briquette production helps in waste reduction and promotes a circular economy.

- High Heat Value: Briquettes generally have a higher calorific value compared to traditional fuels, leading to more efficient energy production.

- Ease of Use: Briquettes are easier to handle, transport, and store than loose biomass, providing convenience for end users.

- Lower Emissions: Burning briquettes often results in fewer pollutants and particulate emissions compared to coal or other fossil fuels.

Conclusion

The briquette making process is a comprehensive procedure that transforms raw biomass into a valuable renewable energy source. By understanding the steps involved, from material collection to final packaging, stakeholders can contribute to energy sustainability and environmental conservation. As the world moves towards greener energy solutions, briquettes present an effective way to harness biomass for practical use, addressing both energy and waste management challenges.

SAYA ALBAIT UNTUK MEMBUAT ARIKEL YANG BERFAEDAH